Statistical Quality Control refers to the use of data and statistical analysis in order to identify the reasons for the variations in quality in industrial processes such as manufacturing. The technique of Statistical Quality Control (SQC) allows us to ensure that there is a degree of uniformity in the manufactured goods and that the minimum industrial standards for quality are attained.

SQC is widely used in industries such as the automobile industry, the electrical device industry, and the chemical industries. We now list out some of the advantages of statistical quality control.

Advantages of Statistical Quality Control:

- It helps in the control, maintainance and improvement of the quality standards.

- Trying to identify assignable causes of variation can help us find out the sources of many production errors. It can also help us to improve the production process by reducing the source of errors.

- Since it is a systematic method, we do not constantly need to keep making changes. There are fixed criteria to tell us when we should take remedial action to correct the production process.

- If the process in control is not giving good enough results, then the quality control standards can be updated to bring them up to the mark.

- It allows us to be certain of the quality of the end product as long as the process is in control. When buying from a particular supplier if the previous lots are good then we can be sure of the quality of the new lots as long as the quality control process continues.

- Sometimes the testing process is destructive. For example, this happens when checking the lifetimes of bulbs. Since we cannot test the entire lot we can only check a sample. The SQC technique assures us of the quality of the entire lot on the basis of the sample.

- The SQC process is efficient in the sense that it reduces the inspection cost by finding the optimal size of the sample that need to be randomly tested.

- SQC is not only used in production processes but also finds applictions in fields such as packaging, scrapping, advertising,etc.

- The presence of quality control schemes enhances the importance of maintaing quality in the employees of the organisation. This is helpful and adds value to the organization in the long term.

- It reduces the waste of time and material because any defects and errors are detected early on and nipped in the bud. The reduction in the cost of production in turn leads to an increase in profits of the company.

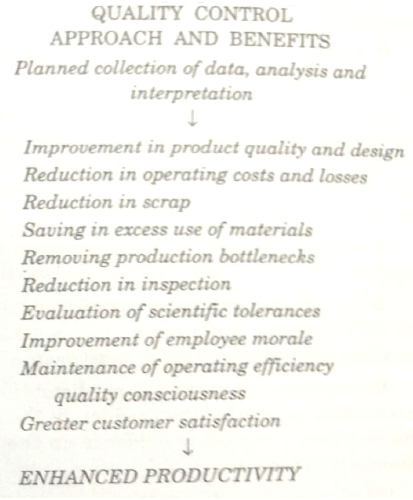

We summarize the above information in the table below.